Introduction to Brushless DC Gearmotors and Motors

Brushless DC (EC) Gearmotors and Motors

What Is a Brushless DC Motor?

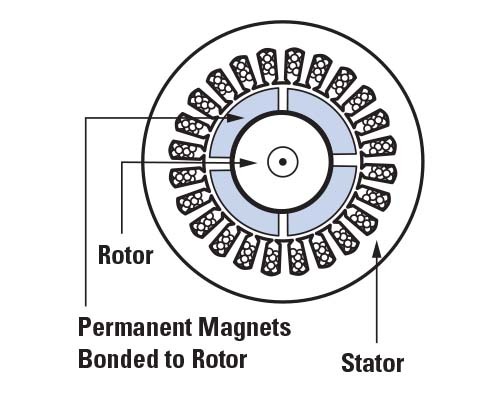

Brushless DC motors, also called Electronically Commutated (EC) motors, are often described as “inside-out permanent magnet motors”. With the traditional PMDC Motors, the magnets were stationary and situated on the stator opposite the windings on the rotor, with BLDC motors, however, the magnets are mounted in connection with them directly to these (the changing part) and place windings on the stator.

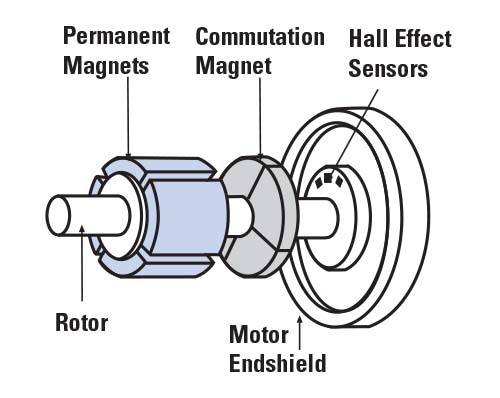

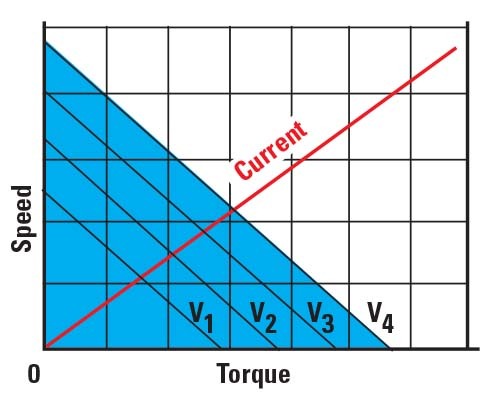

Despite the difference in construction, the BLDC motor's speed-torque characteristic is similar to that of a permanent magnet DC motor. The primary difference is computation; there are no brushes to make contact with the commutator; Winding phases are switched electronically by control circuitry. Hall effect sensors are used to sense rotor position and feed the feedback to the control, which then “knows” when it is time switch winding. This electronics construction eliminates brushes and provides better efficiency and operation reliability.

Advantages of Brushless DC Motors

- Minimal Maintenance: No brushes to check, brush wear or change downtime.

- Life: Longer service life even under heavy conditions.

- Low EMI & Quiet Operation: Great for sensitive laboratory and medical systems.

- High Power Density: outputs more power per frame size than AC or PMDC motors.

- Increased Productivity: Faster acceleration/deceleration and quicker cycle times due to low rotor inertia.

- Linear Speed/Torque Curve: For predictable speed regulation.

- Safe Low-Voltage Solutions: 12V and 24V BLDC motors are ideal for battery operated, mobile or medical applications where electrical safety is a consideration.

Features

- Electronically commutated

- High energy, rare earth magnets used for rotor field

- Requires speed control with 6-lead connection (3 power, 2 Hall Effects, 1 drain)

- Rated speed 2500 RPM; minimum 150-200 RPM

- Linear speed torque curves

- Built-in tach pulse for economical speed readout

- Encoder options for servo performance

Benefits

- No brush wear and no maintenance for less down time

- Quiet, reliable operation

- Easy connections

- More power from a same size motor (BLDC vs. AC 3-phase)

- Higher torque at low speeds than variable speed AC systems

- Higher starting torque than a 3-phase AC, variable speed inverter duty system

- Thermally more efficient than PMDC motor system

Standard Brushless DC Products

Bodine provides an extensive selection of off the shelf BLDC motors, gearmotors and matched drive systems:

- Fully integrated solutions for motor control engineered to be compatible

- 12V, 24V and 130VDC gearmotors, electronic controls

- High speed motors (up to 20,000 RPM) and precision control

- 2 year warranty when motors are combined with Bodine controls

- 22B/SR and 34B/FV 24VDC INTEGRAmotors™ with built-in motor, control, and feedback for a 'power in - power out' solution

Custom Brushless DC Solutions

Bodine engineers also design custom BLDC motor and control solutions to meet unique OEM needs, examples of which include:

- 48B e-motor with type EBL speed control, deliver 1.5 HP output

- Analog (SR) and Digital (FV ) interfaces for INTEGRAmotors

- Optionally environmentally sealed variant for outdoor or rugged applications

- Other third party certifications like Class I, Division 2

- Bespoke control systems for unique performance criteria

Comparison of Different Variable Speed Systems

| Features | Brushless DC | PMDC | AC 3-Phase |

|---|---|---|---|

| Brush wear, brush replacements | Never | Yes | Not Required |

| High torque at speeds above and below rated | Yes | Yes | No |

| Noise Level | Lowest | Higher | Higher |

| Performance | Best | Good | Limited |

| Speed Range | Widest | Widest | Limited |

| Control required | Yes | Yes | Yes |

Applications and Industries

- Lab & Medical Equipment: analyzers, blood; centrifuges; mixers; scanners, MRI/CT

- Packaging Equipment: bottle filling equipment, labeling machines, shrink tunnel, glue applicator

- Factory Automation: conveyors, handling equipment, machining / robots

- Print & Office: photocopiers, wide format printers, printing presses

- Plastics & Processing: Pallet Feeders, Extrusion Support Equipment

- Fluid Handling: Chemical, Lab and Industrial Metering Pumps

- Energy & Remote Applications: solar powered systems, alternative energy, remote sites

- Food Processing Equipment: ovens, Food processing and handling systems

Frequently Asked Brushless DC Motor and Gearmotor Questions:

- Can I make my own extension cable? What do I have to consider?

- Yes, you can make your own cable, however they must have EMI and RFI shielding. Most wiring errors we encounter are due to improper or missing shielding.

- How long can the cable be?

- 50 Feet maximum.

- What is the minimum speed of Bodine brushless DC motors?

- 150-200 RPM, depending on what kind of control is being used.

- What should I check first if a brushless DC motor stops working?

- Check set-up, wire harness and connections.

- My red fault light is on!

- Noise might be coming into the input of the control or there might be overvoltage to control input.

- Can I have preset fixed speed settings?

- Yes, replace the pot with a resistor divider with rotary switch.

- Can we run faster than 2500 RPM?

- Yes, by adjusting the MIN/MAX pot – However, the available speed range will change.