Minimizing Brush Noise in PMDC Gearmotors

Bodine’s 24V PMDC gearmotor delivers low-noise performance for precision lab equipment

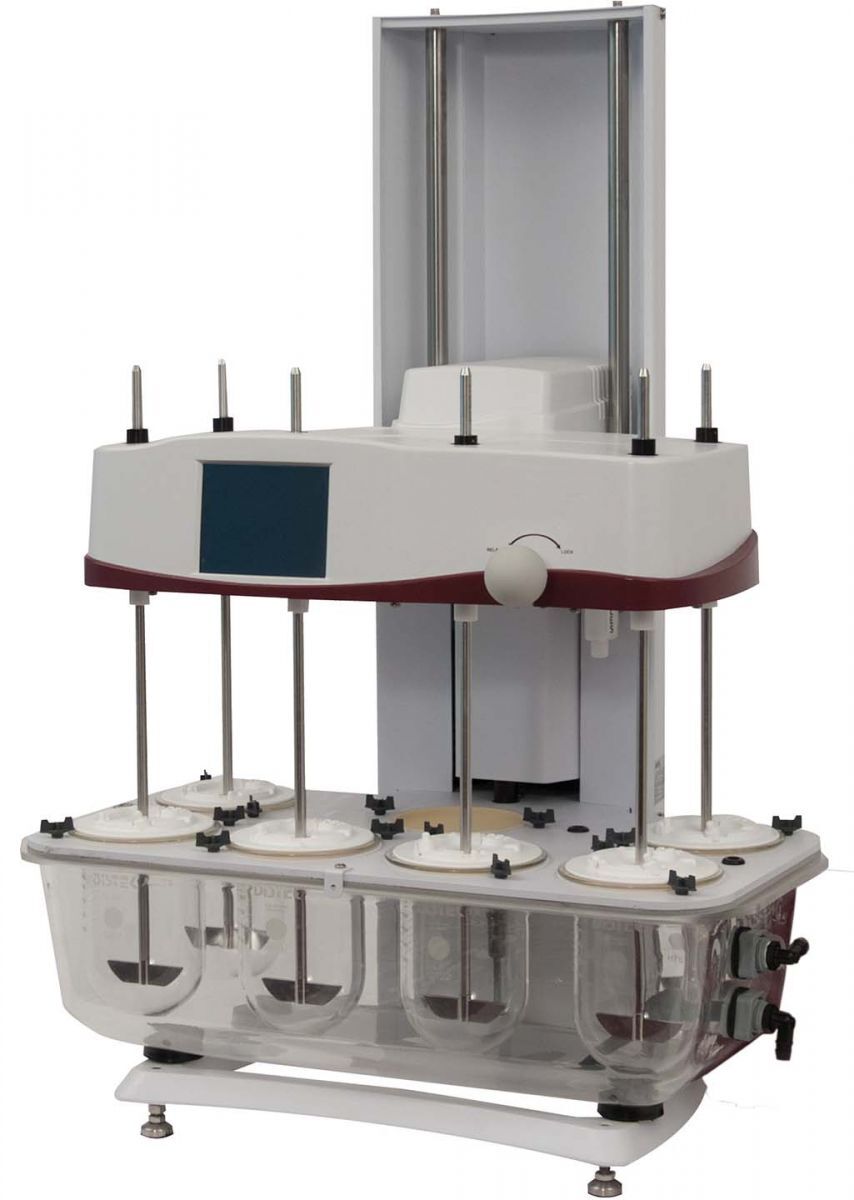

A dominant OEM manufacturer of pharmaceutical dissolution testing equipment chose a Bodine 130V PMDC gearmotor for their flagship product line. Dissolution testing, crucial to the pharmaceutical industry, involves the time it takes for tablets to dissolve in a liquid under standardised conditions. Since Bodine gearmotors had already been successfully used in this type of sensitive application, the manufacturer again approached Bodine for the redesign of a more advanced instrument.

The Challenge: Transitioning to a 24VDC Global Design

The revised dissolution tester was a full redesign that specifically involved normalizing all electronic parts to operate on 24V DC voltage. This method eased adherence to international regulations and enhanced compatibility with overseas markets.

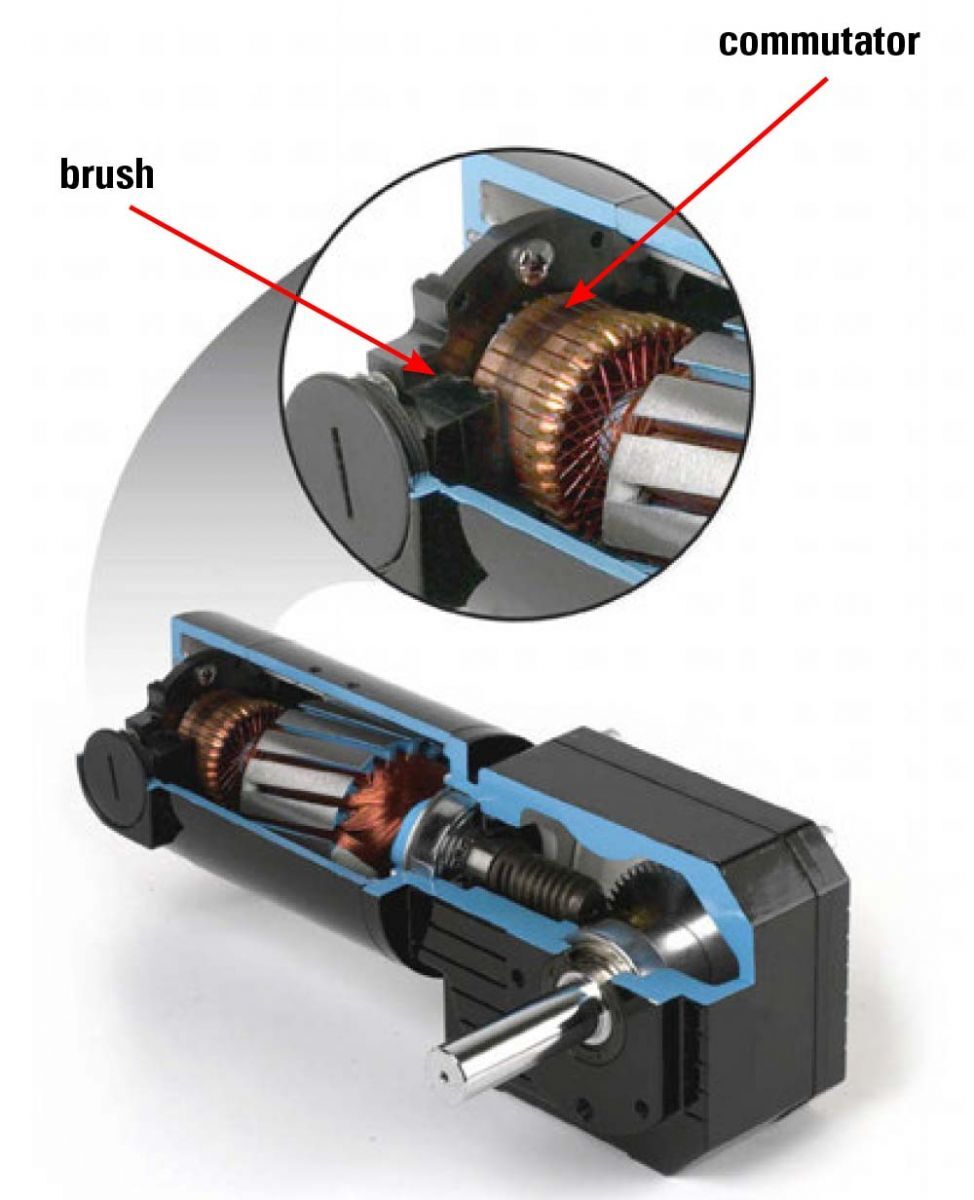

However, when testing Bodine’s 24V gearmotor delivery the OEM experienced slightly more brush noise than with the original, 130V version. All brush motors produce some noise as the brushes hit the contacts in the commutator, particularly when under load, but this sounded louder than anticipated.

Bodine’s Engineering Solution: Electro-Graphite Brushes

Bodine engineers were able to explain fast that 24VDC brush systems are normally louder than those of higher voltage. The team then suggested a simple solution: swapping out the more abrasive electro-graphite brushes for less abrasive ones.

These brushes were made of special materials to lower the friction and spark during commutation thereby reducing the acoustic noise generated by the motor. This change made an immediate difference — the 24V gear motor now ran as quietly as its 130V cousin, and allowed for whisper-quiet operation (that could be used in a pharmaceutical laboratory setting).

Advantages of Bodine’s low noise gearmotor solution

- Less brush noise with electro-graphite brushes

- Same great quiet performance in both the 24v and 130v versions

- Enhanced safety standards for sensitive lab and pharmaceutical applications

- Wide installation around the world, through: System design 24V DC

- Reliable PMDC gearmotor performance in dissolution test apparatus for decades

Quiet, Reliable Gearmotors for Sensitive Applications

This application is a typical example of the Bodine capability to develop “specials” for applications where low noise operation is important including: pharmaceutical testing and laboratory instrumentation. Whatever your product is, it can weigh in with the similar creative engineering. By merging established PMDC gearmotor technology against specialized brush materials, Bodine had the answer to guarantee compliance and keep customers smiling worldwide.

Application Insights

The Design Requirement

Maintain same motor noise level when switching the design from a 130VDC to a low-voltage 24VDC gearmotor.

The Solution

An analysis of the application’s load revealed a standard low voltage brush could be replaced by a better suited, less abrasive electro-graphite brush.