Permanent Magnet (PM) Gearmotors & Motors

Features & Benefits:

Features & Benefits:

- Built for continuous-duty use

- DC-powered (battery or electronic controls)

- During startup or running:Reversible w current limit

- Offers consistent and variable speed

- Provides a starting torque of 175% or more of the rated torque

- High inrush current relative to the full-load running current

Design and Operation: A permanent magnet DC (PMDC) motor is a good choice for DC drive systems that require easy, quick response to changes in load demand, such as those whose jobs need them: Powerful support: In environments where maximum speed accuracy is required throughout the application profile Easy communication. Driven by advances in ceramic and rare-earth magnet technology, as well as modern electronic control techniques, PMDC motors are the answer for adjustable-speed requirements with substantial performance capability in a small, cost-effective package.

What separates PMDC motors from other types of DC motors is that they are wound with a permanent magnet as opposed to a wound field. This eliminates the need for independent field excitation and eliminates this electrical loss that is usually present in field windings.

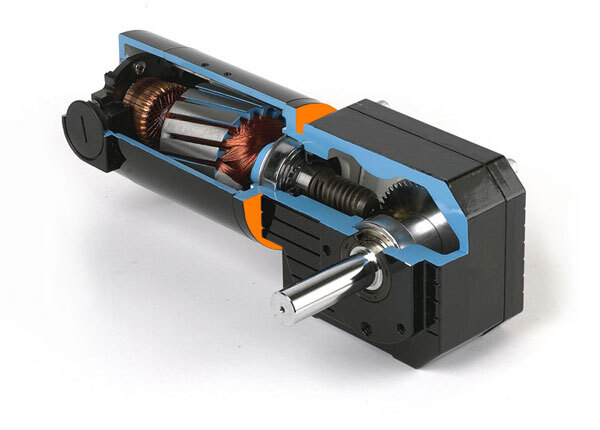

Advantages: Reduction of size is the most significant advantage in using PM field motors (i.e., replacing the wound field with ceramic permanent magnets). The acrylic ring and magnet assembly formed is of a smaller diameter to require less weight, space (see Fig. 1). The field strength of the PMDC motor does not change since there is no armature reaction.

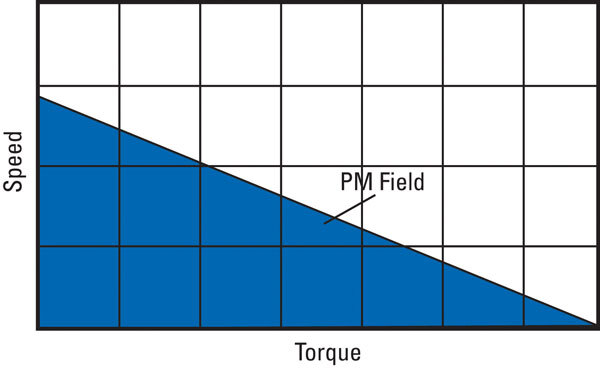

By contrasting the structure of wound field DC (WDC) motor and PMDC, it can be found differences in armature reaction and speed/torque characteristics. In a wound field motor, the magnetizing force of the armature is through a high-permeability iron path. In a PM machine, the ceramic magnets serve as a low permeability path effectively acting like an air gap. This would keep the armature from responding to the field, so that a linear in speed-to-torque relationship is maintained throughout the motor's entire operating range (compare Fig. 2).

Fig. 1: PM motor ring and magnet assembly

Fig. 2: Speed/Torque Curve of a PMDC motor

PMDC motors offer benefits in a number of ways:

1. They generate a lot of Torque at lower RPMs, sometimes needing Gearbox or Gearmotor. PMDC motors are well suited for low-speed applications where backlash or gear windup cannot be accepted. However, they may potentially overheat or the motor burn out if full torque is constantly applied to them.

2. Their torque/speed characteristics are linear and they are easy to control electronically, hence they make excellent adjustable speed and servo motors.

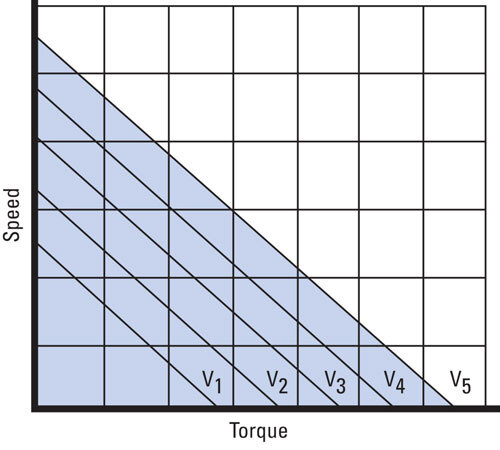

3. In addition, the predictable linear characteristic curves have an advantage that their dynamic behaviour can easily be calculated with mathematics (see Fig. 3).

4. Generally, PMDC motors have a high initial torque that can be beneficial in direct-drives (non-geared motor applications)(and applications with a lot of inertia that require lots of start-up torque but they are also ideal as torque motors in actuator systems and intermittent duty use.

Fig. 3: A typical family of speed / torque curves for a PMDC motor at different voltage inputs, with V5 > V4 > V3 > V2 > V1.

The PMDC motor you get is much smaller but not with a reduction in thermal ratings for a specific horsepower. Their electrical efficiency is as a matter of fact 10 to 15% higher than that of wound-field motors, for they do away with the field copper losses. The products are also offered in TENV (totally enclosed non-ventilated) construction to eliminate the need for cooling fans and other options, allowing for a wider range of mounting configurations.

By having a higher native efficiency, PMDC gearmotors require less current - making them perfect for battery powered/powered hand tools. The permanent magnets are also used for a gentle self-braking function, thereby minimizing shaft coasting when the power is removed. They are dual-leaded (versus the four leads of shunt wound), direction can be changed simply by reversing polarity, utility and impressive durability. Putting the two wires across a brute force short, after they've been disconnected from the power supply, can provide dynamic braking. It gives the same performance as shunt-wound DC motors in nearly all control approaches except field weakening.

Design Considerations: Modern ceramic magnets are dependable, but it is important to know them so as to apply correctly. At cold temperatures (below 0°C), they are also more susceptible to become permanently demagnetized.

Strong armature fields that have potential for permanent demagnetization are particularly problematic during the start, locked-rotor or plug-reversed conditions. Fixed resistance is required in plug reversing power circuit in normal and low temperatures.

The configuration of the power supply is also crucial. Both PWM and SCR controls typically include current regulation/limiting to prevent the motor or gearmotor from being damaged. Real application conditions are different because each LAB PMDC comes with its own demagnetization protection. For low temperature or plug reversing, consult the manufacturer.

Similar to the decay of field flux in wound-field motors as copper resistance increases, PMDC motors suffer from a gradual loss of magnetic flux at higher operating temperatures.

Application information: PMDC gearmotors have very high starting torque and can be easily overloaded in applications with heavy inertial loads or where the motor is required to start under load. These loads can also cause the motor to overrun and present excessive torques to the gearhead for which it is not rated. Users will either use PWM or SCR control with integral current limit, Overload slip clutches are used to protect the gearing.

Fig. 3: A typical family of speed / torque curves for a PMDC motor at different voltage inputs, with V5 > V4 > V3 > V2 > V1.

To explore our DC motor, gearmotor and control products click on these links: